The idea

As solar production is becoming more and more relevant (due to social commitment to the renewable topic but also because of costs reduction), larger and larger power plants are being built worldwide. But large plants means a large areas needed, with two main shortcomings: this kind of areas would usually be far from the cities and/or grid infrastructure, increasing the opex costs, and (especially for developing countries) you must also have a good balance between the necessity of energy and food from crops. So, people started to look at alternative ways.

One of the answers is pretty simple: if you have no more land, why not use water?

Floating photovoltaic (FPV) is a solar application in which PV panels are installed to float on waterbodies such as reservoirs, hydroelectric dams, industrial ponds, water treatment ponds, mining ponds, lakes, and lagoons[1].

In this configuration, you have a lot of benefits (and some cons). In the following, we’ll discuss in some detail the scenario.

How does it work?

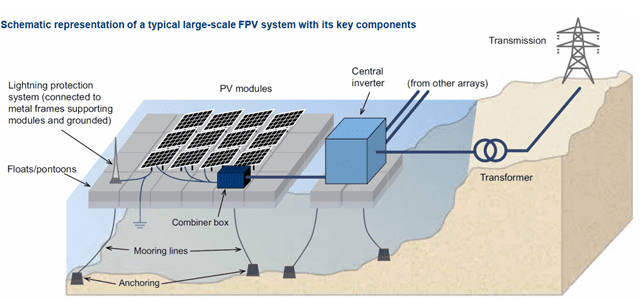

Figure 1: from Solar Energy Research Institute of Singapore (SERIS), “Where the Sun Meets Water”

FPV works just as grounded based PV plants, but with additional mooring and anchoring structures! See fig above.

Why should I invest in this?

PRO:

- Higher energy production performance: improvement in performance of 5-10% is typically observed in comparison with land-based plants, due to different reasons. In particular, the temperature of the panels is smaller due to the cooling effect from the waterbody (both for the presence of the water and because of the wind influence): module temperatures were observed to be lower by 5°C to 10°C, depending on the air ventilation underneath the floating structures.

- Land neutral: the land needed for the installation is greatly reduced in comparison with land-based plant. This is of particular importance in developing countries where land acquisition is critical because in competition to crop-based economy.

- Water evaporation reduction: the FPV plant shades the water surfaces, thus reducing the water evaporation losses. This is of particular importance where drought effect is relevant for the community.

- Sharing existing electrical infrastructure: in the FPV plant is located near pre-existing infrastructures such as hydroelectric plants or irrigations, some of the infrastructure is already there, reducing the construction costs.

- Synergy with hydroelectric power plants: in the FPV plant is located in the same water body of a hydroelectric system, the two plants can be made work in synergy, for example using solar energy during the day and hydropower during the night, or using the water reservoir as a energy storage.

- Ease of cleaning: obviously, the cleaning system has water immediately available.

- Easy installation and deployment: the FPV plant construction and installation do not require civil work to prepare the site, and the float units are prefabricated. For example, a major FPV developer from China recently reported that a 1 MWp system can be installed by 50 people in one day, provided that a supply chain is in place[2].

CONS:

- Higher capital expenses

- Higher PV component costs: PV panels must be more resilient wrt ground structures.

- Higher installation costs (generally, the design: the floating platform, the anchoring and mooring systems, the cabling)

- Environmental impact: there are some unknown issues about possible environmental impact on the marine biomes. On the contrary, FPV could also limit the algae growing, that is a common and relevant problem especially in artificial waterbodies.

- Long term impacts uncertainties: generally speaking, the PV technology is mature and largely exploited. Even if FPV tech is around since 2007, it is only since 2017 that there has been a numerical significative presence of this kind of plants worldwide (cumulative installed capacity>550MWp), so we have uncertainties on long term behaviours.

- Experience/level of maturity of FPV: Cumulative capacity as of end of 2018: >1.3 GWp and 5 years of experience with large-scale projects (2015 as kickoff).

- Experience/level of maturity of PV: Cumulative capacity as of end of 2018: >500 GWp, Thousands of projects built in 10–30 years of experience.

In addition, marine-grade materials and components are critical for these installations, which must withstand the prevailing environmental conditions. Operation and maintenance costs for near shore PV are also expected to be higher than for inland installations. [2]

- Extreme events: “Regarding the resilience of the project, questions emerge about the development of climate change. For any project, implemented anywhere in the world, climate change is going to be a risk because we cannot always rely on historical weather data to project weather events”. [3]

As solar production is becoming more and more relevant, larger and larger power plants are being built worldwide. But large plants means a large areas needed.

So, people started to look at alternative ways. One of the answers is pretty simple: if you have no more land, why not use water?

Real world: a photobook

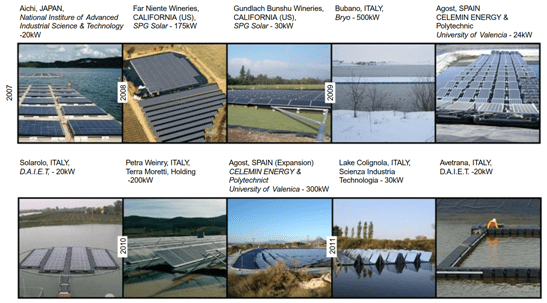

Figure 2: from “Submerged and Floating Photovoltaic systems, Marco Rosa-Clot and Giuseppe Marco Tina

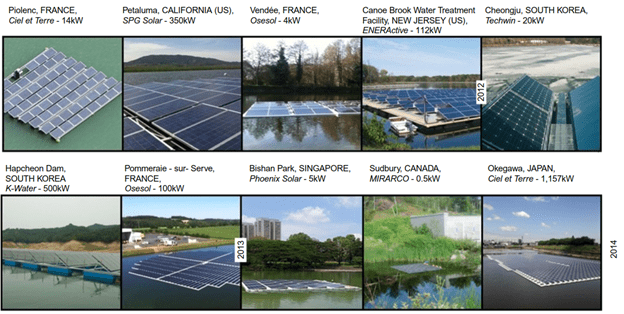

Figure 3: from “Submerged and Floating Photovoltaic systems, Marco Rosa-Clot and Giuseppe Marco Tina

Your take-home message

If you are a FPV asset owner, O&M manager or you want to invest in this market, you should be aware of pro and cons. In particular, we expect that since the environment is more harsh, Operation and maintenance costs are expected to be higher than for inland installations. Additionally, O&M typical activities such as replacement of parts of the equipment is more complicated and time intensive in comparison with ground-based pv plants.

Thus, the need of an effective monitoring system is very valuable, especially if it is able to consider weather effects as input of the data analysis.

Once upon a time: if you want to know the tale…

In 2007, the National Institute of Advanced Industrial Science and Technology (AIST) built the world’s first FPV plant of 20-kWp capacity in Aichi, Japan. Later in 2008, the first commercial-scale installation of capacity 175 kWp came up at “Far Niente Winery”, California, USA. Most of these early projects were small-scale systems with research and demonstration purposes. From early 2013, megawatt scale plants started to appear in Japan and South Korea. Since then, the path was opened… see graph!

Figure 4: from World Bank Group, ESMAP and SERIS. 2019. Where Sun Meets Water: Floating Solar Market

Notes

[1] Mohit Acharya and Sarvesh Devraj,»Floating Solar Photovoltaic (FSPV): A Third Pillar to Solar PV Sector ?, TERI Discussion Paper, 2019. (See reference)

[2] World Bank Group, ESMAP and SERIS. 2019. “Where Sun Meets Water: Floating Solar Market Report”. Washington, DC: World Bank. (See reference)

[3] https://www.solarplaza.com/channels/markets/12199/how-could-floating-solar-help-island-nations-decarbonize-their-power-systems/ (See reference)

For the curious costumer

At i-EM S.r.l. we have what you need (we hope!)… Try us!

Author

Fabrizio Ruffini, PhD

Senior Data Scientist at i-EM